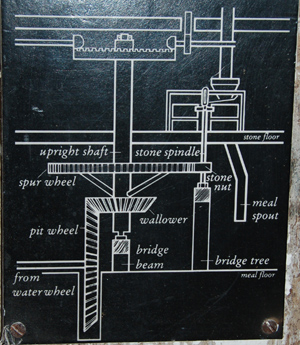

Pakenham Mill close up on powertrain

Showing how power is converted to drive the millstones |

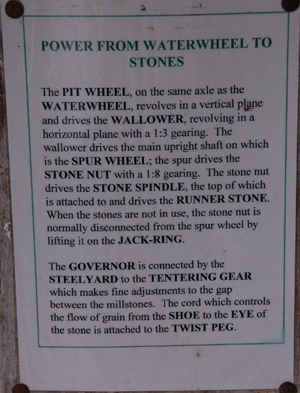

Pakenham Information Board 7

Describing how power is transmitted to grind corn through each gear and shaft |

The pitwheel and wallower |

Lifting the stone nut off the Jack Ring

That is to say, engaging the gear which connects the drive train to the millstones |

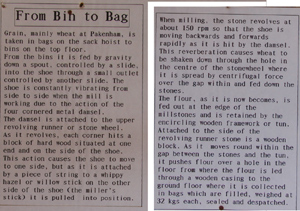

Information boards explaining how the corn moves from sacks to millstone to flour bags |

Wheat enters the complex control system of the grindstones to be milled into flour. The chain that you see is used to hoist grain sacks to the top of the building, in order to feed wheat into the hoppers. |

As the millstones turn, this governor makes small adjustments to the gap between the stones via the steelyard |

Display of a millstone

Also showing the tools used to dress a worn stone.

Pakenham mill has three millstones, but today, only one is kept in use. |

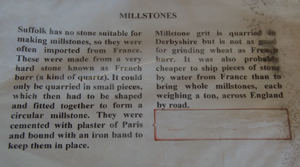

Pakenham Information Board

Describing how 19th century millstones were constructed from sections of French burr |

An old millstone showing the stone sections |

In 1942 this Blackstone paraffin engine was installed to drive a new roller mill set up, to allow white flour to be made much more profitably. The engine was made in 1904, and installed in 1942 by the mill's owner at the time, Mr Marriage. |

The millpool receives the water after passing through the mill, and also any water from the millpond overflow. |

|

|

Plaque erected by Charles Lowe to commemorate his completion of the mill's renovations, carried out in 1813 to 1814. In 1813 Lowe, a prosperous miller at Ixworth, leased Pakenham watermill and its 40 acre farm from the Leheu family for £130 pa. He agreed to spend £400 on improvements, despite the mill being only 15 to 20 years old. He replaced the undershot wheel with a very large breastshot wheel of wood and iron, which also meant that he had to raise the banks of the millpool to bring the water level up to breastwheel height, giving a 10 feet fall. |

|